Enhancing Efficiency and Innovation with Custom Plastic Injection Molding Services

In today’s competitive manufacturing landscape, companies are constantly seeking ways to innovate and improve their production processes. One of the most effective strategies to achieve this is through custom plastic injection molding services. This advanced technique not only allows for the production of complex parts but also ensures high precision and consistency. At Sumiparts, we specialize in delivering top-notch injection molding solutions tailored to meet the unique needs of our clients.

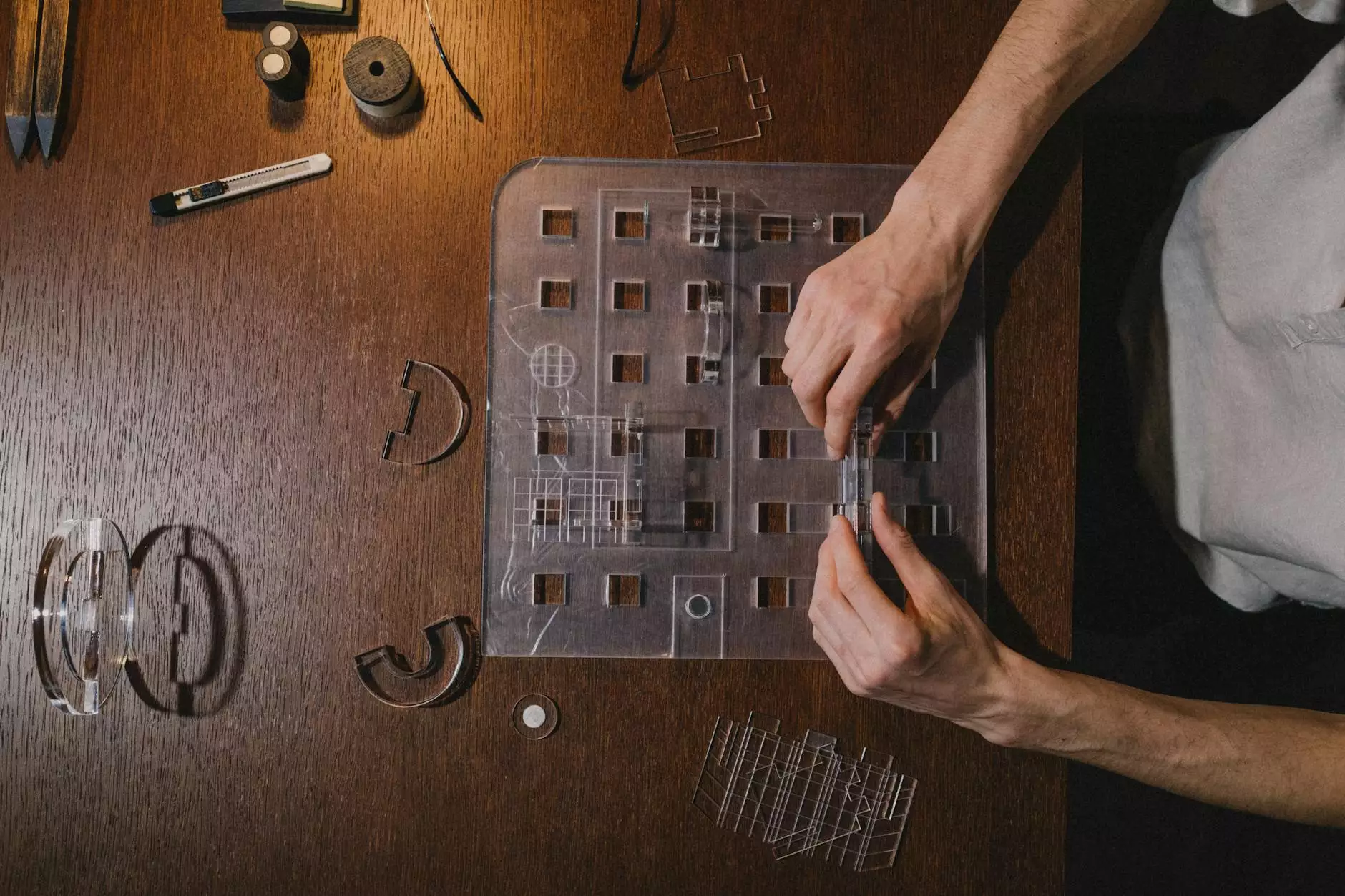

Understanding the Basics of Plastic Injection Molding

Plastic injection molding is a manufacturing process used to create parts by injecting molten plastic into a pre-designed mold. This technique has become increasingly popular due to its efficiency, speed, and ability to produce intricate shapes. The process consists of several key stages:

- Material Selection: The right type of plastic is chosen based on the part requirements, including durability and flexibility.

- Mold Creation: High-quality molds are designed and fabricated to create the desired part shape.

- Injection: The chosen plastic material is heated until molten and injected into the mold at high pressure.

- Cooling: Once the mold is filled, the material is allowed to cool and harden, taking the shape of the mold.

- Demolding: After cooling, the mold is opened, and the finished part is removed.

The Advantages of Custom Plastic Injection Molding Services

Choosing custom plastic injection molding services can provide numerous advantages for manufacturers, including:

- High Efficiency: Injection molding allows for the rapid production of large volumes of parts, significantly reducing manufacturing time.

- Cost-Effectiveness: Although the initial investment in molds can be high, the cost per part decreases dramatically with mass production.

- Precision and Consistency: This method allows for tight tolerances and uniformity across all produced parts, ensuring quality control.

- Material Versatility: A wide range of plastic materials can be used, allowing for customization based on specific applications.

- Complex Geometries: Injection molding can create intricate and complex designs that might be impossible to achieve with other manufacturing techniques.

Applications of Custom Plastic Injection Molding Services

The applications of custom plastic injection molding services are vast and varied, making it an essential process across numerous industries:

Aerospace Industry

In the aerospace sector, lightweight and durable components are critical. Custom plastic injection molding creates parts that help reduce overall weight and improve fuel efficiency.

Automotive Manufacturing

The automotive industry relies heavily on molded plastic parts for various components, including dashboards, interior fittings, and exterior trims, providing both aesthetic and functional benefits.

Consumer Electronics

As technology advances, the need for sophisticated electronic housings and components has grown, making injection molding the go-to choice for manufacturers in this sector.

Medical Devices

Custom molding services are critical in producing precise and hygienic medical device components that adhere to stringent industry regulations.

Household Products

From storage containers to kitchenware, custom plastic parts produced through injection molding can be found in many household items, combining functionality with design.

The Role of Technology in Custom Plastic Injection Molding Services

Innovations in technology have significantly enhanced the efficiency and capabilities of plastic injection molding. Companies like Sumiparts invest in state-of-the-art machinery and software to optimize the molding process:

- 3D Printing: Rapid prototyping through 3D printing enables manufacturers to create and test mold designs quickly before full-scale production.

- Advanced Monitoring Systems: Real-time monitoring of temperature, pressure, and material flow ensures consistent quality and reduces waste.

- Simulation Software: Using software to simulate the molding process can help identify potential issues before production, saving time and resources.

- Robotics: Automation of material handling and part removal increases speed and reduces the risk of human error.

Choosing the Right Custom Plastic Injection Molding Services Provider

When selecting a provider for custom plastic injection molding services, certain key factors should be considered to ensure you partner with a capable and reliable manufacturer:

- Experience and Expertise: Look for a company with a proven track record in the industry and expertise in handling projects similar to yours.

- Quality Certifications: Ensure that the provider adheres to industry standards and possesses requisite certifications, such as ISO 9001.

- Custom Capabilities: The provider should be able to customize their services to meet your specific needs, including material selection, design, and production volumes.

- Advanced Technology: A focus on the latest technology indicates a commitment to quality and efficiency.

- Customer Support: Good communication and support are critical for addressing concerns and ensuring your project stays on track.

Understanding the Costs Associated with Custom Plastic Injection Molding Services

The cost of custom plastic injection molding services can vary based on several factors:

- Mold Design and Fabrication: The complexity of the mold design directly affects the costs, with more intricate designs requiring more time and resources to fabricate.

- Material Selection: The type of plastic used can influence costs, as some materials are more expensive than others.

- Production Volume: Higher production volumes typically lead to lower costs per part, making it essential to assess your needs accurately.

- Additional Services: Additional services such as finishing, assembly, or packaging can also impact the overall cost.

Case Studies: Success Stories Using Custom Plastic Injection Molding Services

Numerous companies have successfully leveraged custom plastic injection molding services to create innovative products. Here are a few notable examples:

Case Study 1: Automotive Component Manufacturer

An automotive parts manufacturer partnered with Sumiparts to develop high-performance plastic components for a new vehicle model. By utilizing injection molding, they achieved significant weight savings and reduced production time.

Case Study 2: Medical Device Innovation

A medical device startup required precision components for their new product. By employing custom molding services, they ensured high quality and compliance with industry regulations, allowing them to bring their product to market faster.

Conclusion

In summary, custom plastic injection molding services offer a robust solution for businesses seeking efficiency, precision, and innovation in their manufacturing processes. By understanding the advantages, applications, and technology behind this method, companies can make informed decisions that enhance their productivity and product quality. At Sumiparts, we are dedicated to providing unparalleled custom injection molding solutions that meet and exceed our clients' expectations.

For more information about our services, please contact us or visit our website to explore how we can assist with your plastic injection molding needs!